-

Z SeriesZ SeriesOur latest systems achieve an extremely high output and dose which greatly increases cure speeds offering customers a wider choice in all applications.

Z SeriesZ SeriesOur latest systems achieve an extremely high output and dose which greatly increases cure speeds offering customers a wider choice in all applications. -

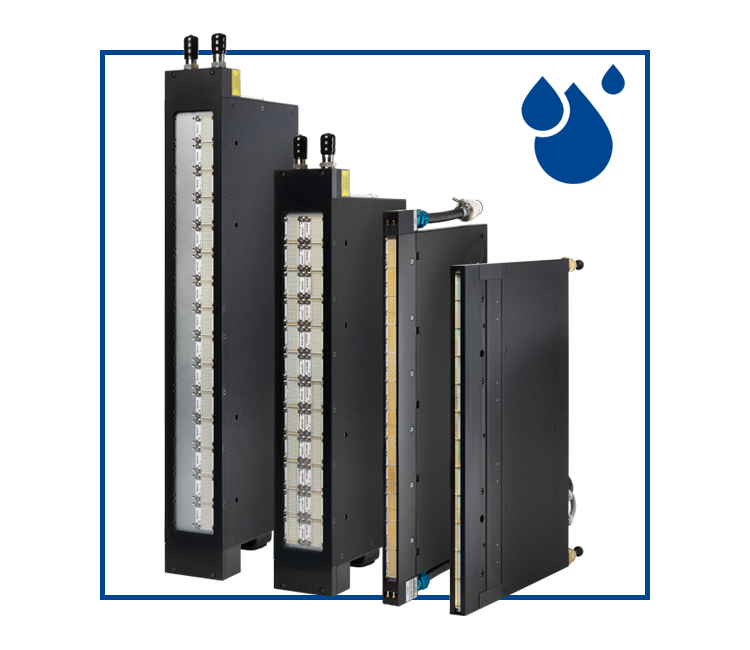

C SeriesC SeriesSTEADYcool for water-cooling, offering a consistent, quieter and steady cooling performance. With XT8 UV LED Booster technology.

C SeriesC SeriesSTEADYcool for water-cooling, offering a consistent, quieter and steady cooling performance. With XT8 UV LED Booster technology. -

AC SeriesAC SeriesThe highest intensity UV LED handheld products available on the market for automotive and industrial UV curable paints, fillers, adhesives and topcoats.

AC SeriesAC SeriesThe highest intensity UV LED handheld products available on the market for automotive and industrial UV curable paints, fillers, adhesives and topcoats. -

SubzeroSubzeroDesigned specifically for inkjet curing applications, the reduced footprint and ultra-light weight allows for their use in small UV inkjet systems.

SubzeroSubzeroDesigned specifically for inkjet curing applications, the reduced footprint and ultra-light weight allows for their use in small UV inkjet systems. -

UV SanitiserUV SanitiserDesigned to inactivate biomolecules and micro-organisms including the elimination of Coronavirus, for use on all surfaces.

UV SanitiserUV SanitiserDesigned to inactivate biomolecules and micro-organisms including the elimination of Coronavirus, for use on all surfaces. -

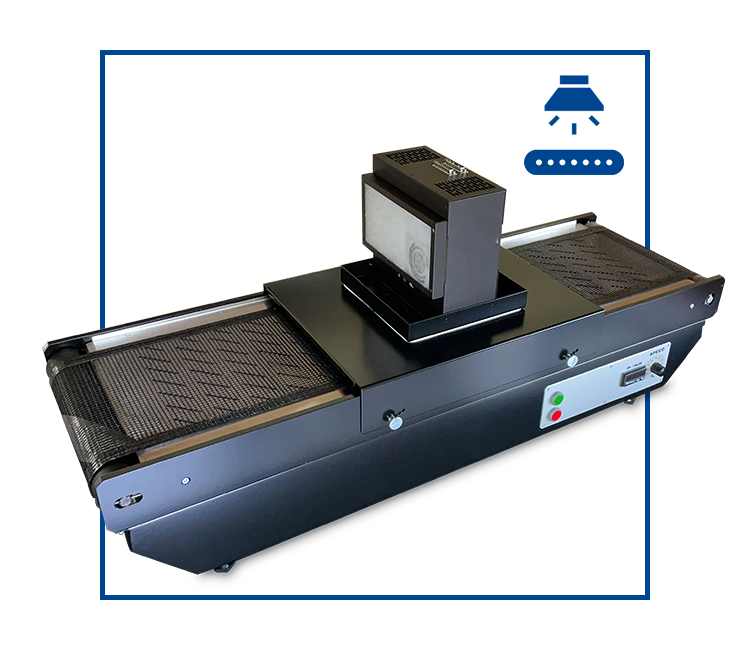

UV ConveyorUV ConveyorOur versatile UV Curing Conveyor Systems are designed for the curing of inks, adhesives, coatings and encapsulants.

UV ConveyorUV ConveyorOur versatile UV Curing Conveyor Systems are designed for the curing of inks, adhesives, coatings and encapsulants. -

UV MeasurementUV MeasurementAccurately measuring the dose and intensity is crucial to establishing a specification for UV curable products and maintaining a process window.

UV MeasurementUV MeasurementAccurately measuring the dose and intensity is crucial to establishing a specification for UV curable products and maintaining a process window.

You are here | Home